Mold Flow Analysis

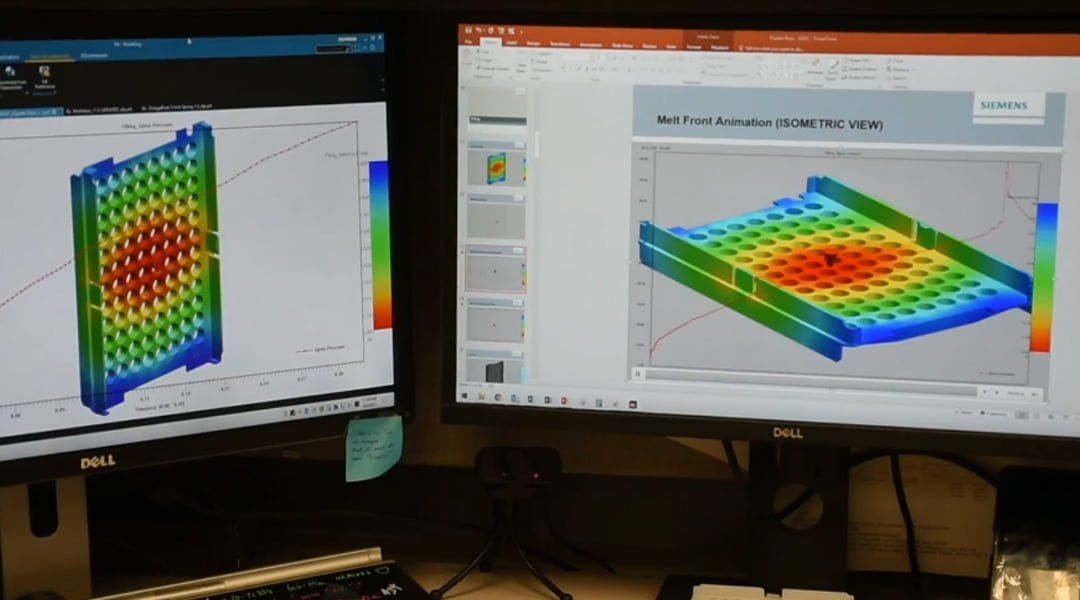

Before the injection molding process begins, a Mold Flow Analysis is conducted to identify potential problems and improvements for a mold before it gets built. Using specialized software, we simulate an injection molding cycle: molten plastic is injected into a mold cavity by a reciprocating screw, where it conforms to the mold shape and then cools to be extracted. There are tens of thousands of different polymers, elastomers, thermoplastic, and thermoset materials. They display different properties when heated and cooled, including color, clarity, sheen, tensile strength, and flexibility.

Being able to simulate how the polymers will react under different conditions gives incredible insight. But we can also see what’s going on inside the mold itself—particularly useful for any product with varying wall thicknesses or challenging geometry. At this point, we can adjust the design, determine the correct placement of the gate, choose the correct polymer, regulate the heating and cooling, control the flow and injection pressure, and essentially optimize the entire production process.

Mold Flow Analysis is a meticulous, hands-on-process. In a world of faster, better, cheaper—Precision Group believes in getting it right the first time. Mold Flow Analysis is a crucial step in our commitment to quality, and the attainment of great engineering. We believe it is a critical step for our clients—the results provide less risk, save time and money in adjustments, and optimize the injection molding cycle. And we just enjoy making you look like a hero.