With specialty molds, Precision Group has Mexico in its sights

Thanks to a very positive market expectation in Mexico, with the specialty in mold creation, Precision Group opted for the opening of a new operation in Monterrey last January. In this headquarters they offer repair and maintenance services for molds, although the idea is to take its capacities towards the manufacture of tools and the molding of parts.

Precision Group is an experienced manufacturer of molds, with the ability to provide solutions that range from the concept and design of a product, to everything related to the mold and, even, the production of plastic parts for the medical, automotive, aerospace markets. , energy, electronics and consumer. Although his clients today are major Fortune 500 companies, Precision Group has painstakingly carved his own path to get there.

The origins of the company go back to a dream of entrepreneurship of Maya and Naum Royberg, who fled the former Soviet Union and came to Texas in search of freedom and well-being. The idea, which began in the garage of his home, today spreads to four locations: two in Texas and two on Mexican soil. With their most recent investment, a workshop in Monterrey, the Roybergs are committed to further globalizing their operation and being prepared for the manufacturing boom expected in Mexico.

Plastics Technology México had the opportunity to visit its corporate offices in San Antonio, in order to see first-hand its technological capabilities, their business culture and its expansion plans to serve their clients from the Mexican Republic. Its strategy is based on working with cutting-edge technology and the development of human talent. This is their story.

The origins of the company date back to an entrepreneurial dream of the husband and wife Naum and Maya Royberg, who fled the former Soviet Union and arrived in Texas in 1978, Precision Group has painstakingly carved his own path to get there.

Building a dream

Precision Group’s owners arrived in the United States around 1978. Young people and a small four-year-old daughter, ventured to get away from his country, in full political repression. After a journey of dangers and uncertainties, as seen in the films of the Iron Curtain era, fate led them to San Antonio, Texas. Without knowing English, and with only $200 in their pockets, they began to work in different companies and in several shifts. Years of striving to learn the language and make a living followed, until around 1985 they saw the time to take the next step.

“We had always nurtured the dream of being entrepreneurs and founding a business in which we could deposit my husband technical knowledge and pour all our work capacity into building something of our own. So we decided that this was what we wanted to do, and we started in our garage. My husband made sketches and mold designs, and I had two jobs to support the family financially. When we embarked on this adventure we knew it was going to be difficult, but also exciting for what we could achieve. And so it was, ”

Ww remember that the first mold developed was for an entrepreneurial couple, like them, who came from Austin. “They had a limited budget, but for us it was a great opportunity. They hadn’t found anyone who could mold them for the price they were looking for and we did. With this collaboration, both they and we were able to start doing business. Even today we have saved the piece that was manufactured with that mold ”.

A year later, pressure from their neighbors, who did not want a commercial operation nearby, led them to rent a small warehouse in an industrial park. As its capabilities and reputation increased, so did its customer base. Thus, by 1990 they expanded their operations and established a new workshop in La Feria, Texas. The following year they increased their area of operation in San Antonio to about 900 square meters, which allowed them to offer more services to the automotive industry.

Shortly after, 1995 was a year of great movement: they expanded the San Antonio headquarters again, reaching some 2,000 square meters and adding other capacities. They also set foot on Mexican soil with the opening of a workshop in Reynosa, Tamaulipas. “This decision was motivated by maquila clients for the automotive industry, who required our services on that side of the border. With the maquiladoras, the demand for manufacturing grew exponentially and we were there to attend to it ”.

In 2005, the Precision Group took another big step toward building its current identity with the creation of its in-house plastic part molding division. By adding injection molding to their offering, they could give their customers a comprehensive concept-to-part solution. “Being a mold maker and also supporting our clients with mold repairs, I told my husband that the key would be to have the entire turnkey operation. That way, we wouldn’t have to send the molds to another place for testing, but we could do it at our plant”.

Precision Group has the ability to provide solutions ranging from the concept and design of a product, to everything related to the mold and even the production of plastic parts.

It was not an easy decision. There was the fear that their customers might see them as competitors in the molding segment, but they did not. They became what can be called a one-stop shop. “By having injection machines, our service in mold manufacturing acquired an added value for the molders and, on the other hand, those clients who wanted to contract the mold and the manufacturing in a single stop could do it with us”.

They began with tests and validations, then small productions followed, until in 2014 they allocated an area dedicated to molding within the plant to meet larger requirements. In 2019 they obtained ISO certifications for the manufacture of molded plastic components for medical devices.

The most recent milestone is in 2021: last January they made another strategic move with the opening of the workshop in Monterrey, Nuevo León, under the name of Prodmash.

Technologies and talent to go from concept to piece

“It all starts with technology, which is a priority for us. We were the first in Texas to bring a five-axis machining center to San Antonio more than 10 years ago. When we are going to acquire a new technology we do a deep evaluation to know what the system is capable of doing and contributing. Then we make sure to train, educate and prepare ourselves to be able to use it at its highest level. We always wanted to differentiate ourselves from other companies through the use and application of technology. Going to the forefront brings the challenge of education and training, but we understand it and that is how we operate ”, said the board of directors.

Precision Group is a regular visitors to industrial machinery fairs, where they have been able to learn about new trends and take the step to understand, acquire and manage them. When they started in the business, designs were made in sketches and drawings, but everything has changed and they have followed their instinct to advance in this sense, as technology does.

The board of directors recalls that, once, when the company was in its infancy, a purchasing manager of a company in the automotive industry, with whom they were already working on several projects, asked them to implement 3D simulation software. “It was very expensive and we did not know about this application, but it was an opportunity to generate more business. So we had to jump over that hurdle and take the risk. We bought the system, we trained to work with it, and that gave us a competitive advantage with other clients. These steps must be taken.”

“Our team uses the best design tools available to capture the ideas that clients bring up. All aspects of the design are captured in a single 3D CAD master model created by designers in our tooling department. The software creates a complete 3D product definition and enables a simulation that assesses productivity issues long before a prototype is built. “

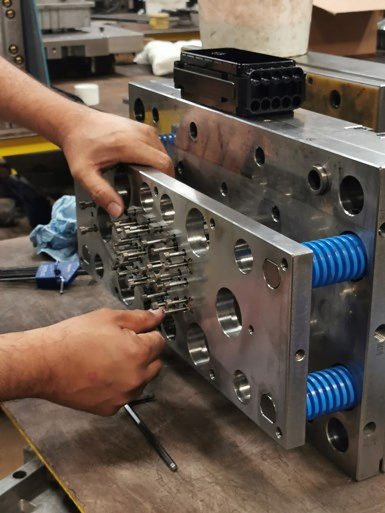

Today, its mold making capabilities span complex machining jobs for world-class customers and include direct machining, four-axis CNC lathe, five-axis high-speed CNC, wire EDM and EDM. The company also has the capacity to provide its customers with a “quick mold” or prototype, made of aluminum, so that they have a more precise idea of the appearance of the final products before going to production.

For injection molding they have electric machines equipped with robots that allow a clean and automated operation. Secondary operations include semi-automatic assembly, in-mold decoration, pad printing, ultrasonic welding, overmolding, and engineering services.

We have a special place in the Precision Group facilities dedicated to preserving recognition and parts for our customers, from all her years in the market.

Another division of the Precision Group that is very important in the company’s strategy is the maintenance and repair service of molds for industries as demanding as aerospace, automotive and white goods. In their repair arsenal they have the HTS precision laser welding system, which allows extremely precise welds, up to 50 microns. “This system is essential for cavity or core mold repairs. Cold welding is done with the same steel as the mold, and it can be done with dimensions thinner than a hair. The operation is so precise that a microscope is required. This allows to speed up the times with respect to traditional methods. Currently, each workshop has a laser welder and the newest is in Monterrey ”, commented the CEO.

In addition, the Precision Group offers its customers mold preventive maintenance programs, which allow a scheduled review and adjustment of the mold to be coordinated before a failure occurs. “If there is an unexpected failure, the customer loses money by the time their production stops and the mold does not produce on the machine. By doing it programatically, this is avoided ”.

One strength that they stand out is that regardless of the challenge, be it repair or manufacture of molds or plastic injection, all its headquarters in the United States (San Antonio and La Feria) and in Mexico (Reynosa and now Monterrey) operate in coordinated manner. “We are a single company, in which the teams work across four facilities, but as if it were a single roof.”

The bet for Mexico

In Mexico, we see the future. From the Reynosa headquarters they serve the dynamic market for maquiladora on the border, but they see a great opportunity to go further inland on Mexican soil to get on what will be the manufacturing wave expected in the country, as a result of the trend of nearshoring, through which large multinationals seek to have the manufacturing of their products closer to their corporations. “Several of our clients are casting their eyes on Mexico, but also several Mexican companies require the proximity of a supplier with the capacities and skills that we offer. We are certain that our work will have much more recognition and scope, with Mexico as a platform. The five-year plan looks great”

Although the pandemic delayed the plans to start the operation in Monterrey, they kept their intention firm, and in January of this year they began activities.

“In a crisis, everyone falls back, but this was the time to invest. Setting up a workshop takes time. You have to find the building, install the crane, do the refurbishment, buy machinery and much more. We were able to take advantage of this time to prepare and thus, when the reactivation of business arrives, we are ready to provide services. We are ahead of the curve ”.

Currently, we already work with several clients in the automotive industry in repair and maintenance of molds, but the idea is to take the Monterrey workshop step by step towards the capabilities of mold manufacturing and injection molding. “Today we can provide the service from our other locations, but the idea is to do it locally, with the same quality”.

One of the challenges that Precision Group is working on for the development of Prodmash, the name under which it operates in Monterrey, is the development of human talent and technology transfer. “In Monterrey we will have the same technologies that we have in San Antonio. Now we are in a phase of training and preparation of personnel. Several of our engineers have traveled to teach the operation of systems and equipment. From Monterrey they have also come to San Antonio. However, we need more education, so we plan to establish alliances with technical schools in Mexico to advance in this regard. You have to invest in people with a view to the future. It is not only having the best technology but also the best people, the most prepared, so that they can operate it ”.

We assure that in all our locations we have sought to replicate the culture that characterizes the Precision Group. “We are a family business. We care about people and their well-being. Finding this vocation gave us a purpose and a future. Even from when we were in the garage, our goal was to create a good place for people to want to work. We have a great connoisseur of this field, enjoys educating people and helping them reach the next level. We like to share our knowledge of technology. For years we have educated ourselves and passed that knowledge on to our employees, who are proud of their work and what they do. And that vision prevails in all the projects we undertake. In Mexico, we are excited to take part of who we are and do something that represents opportunities for education, development, profession and future ”.

“Mexico is a shining star. With great potential in its people, in manufacturing and at all levels of development. I can only say that we are happy to be part of this great revolution ”.

World-class clients

Precision Group define their molds as complex, both geometrically and dimensionally, for various industries. Hence, its clients are in the most demanding sectors. They had the opportunity to work on a component for a NASA project, so it can be said that their molds and parts have reached space. “The knowledge and the ability to develop these projects is teamwork. It is not something that happens overnight, but a process that takes time. In addition, the cooperation with the client is essential to share information and manufacture the mold with all the specifications that it requires ”.

One case is that of a renowned American company of scientific instrumentation and consumables, which came to them to manufacture a mold intended to produce a part with a highly additive resin. “Our comprehensive knowledge allowed us to work with them on mold development and consider the shrinkage variables of such a particular resin. This was indispensable in the design of the mold ”.

Now, during the pandemic, they were listed as part of the production chains for essential activities. In record time they worked with a large multinational company to develop the plastic components in test kits for the diagnosis of COVID-19. “We quickly accommodate tooling, maintenance and repair needs to support them.”

An application that illustrates very well its comprehensive ability to provide a turnkey solution, from concept to part, was for a client in the pharmaceutical industry, who had a project for the manufacture of implements for artificial insemination. “It was a whole process to meet them, understand the concept of what they required and gain their trust so that they would allow us to give recommendations throughout the process. It was a very specific piece, and although we do not have knowledge in the medical area, our experience in manufacturing gave us clear insights into what the design had to be in order for it to work in production. We support them in the design, the manufacture of the mold and the injection of the parts. With each client it is a different process”.