Clean Room Efficiency: Precision Group Tooling and Molding Sets the Standard

Introduction

In the world of manufacturing, maintaining high-quality production standards while minimizing waste is a constant challenge. Clean rooms have emerged as indispensable environments for ensuring precision and waste reduction in industries that demand an ultra-clean and controlled workspace. This article explores the pivotal role of clean room efficiency in optimizing production processes and reducing waste, with a special focus on Precision Group Tooling and Molding, a leading participant in this field, boasting a Clean Room Class 8 Certified Facility.

Understanding Clean Room Efficiency

Clean rooms are specialized environments engineered to maintain exceptionally low levels of airborne particles and contaminants. They are a critical component in industries such as pharmaceuticals, electronics, medical devices, and aerospace, where the slightest particle contamination can result in product defects, regulatory issues, and loss of consumer trust. To appreciate their role in optimizing production processes and waste reduction, let’s delve into key aspects:

- Product Quality Assurance: Clean rooms are essential for industries that produce sensitive or sterile products. By providing an environment with minimal contaminants, they assure product quality, reducing the risk of defects and costly recalls.

- Enhanced Precision and Productivity: Clean rooms enable the use of high-precision equipment and advanced technologies that result in faster and more precise production. This efficiency is crucial, especially in semiconductor manufacturing and medical device assembly.

- Waste Reduction: The controlled environment of a clean room significantly reduces the risk of product contamination and defects. Consequently, this minimizes waste production, leading to cost savings and environmental benefits.

- Regulatory Compliance: Clean rooms are crucial for industries that must adhere to strict regulatory standards. Precision Group Tooling and Molding’s Clean Room Class 8 Certified Facility ensures compliance, mitigating the risk of regulatory fines and penalties.

Precision Group Tooling and Molding: Setting the Standard for Clean Room Efficiency

One key player in the clean room manufacturing sector that has consistently raised the bar for clean room efficiency is Precision Group Tooling and Molding. They operate a Clean Room Class 8 Certified Facility, which is a testament to their unwavering commitment to quality, precision, and innovation.

Here are some compelling reasons why Precision Group Tooling and Molding is a noteworthy participant in the world of clean rooms:

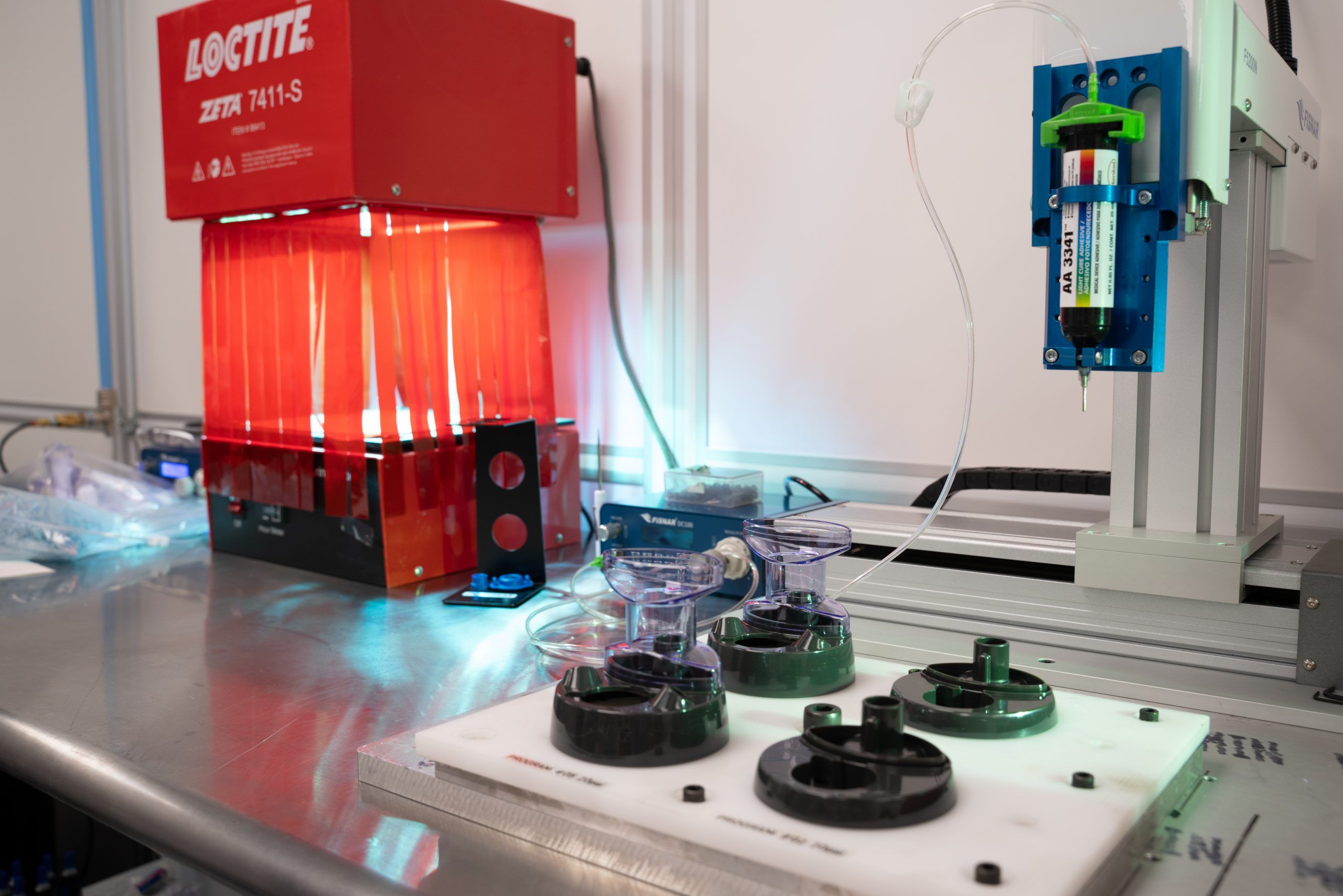

- Cutting-Edge Facilities: Precision Group’s Clean Room Class 8 Certified Facility boasts state-of-the-art infrastructure. It includes advanced HVAC systems, HEPA and ULPA filtration, and meticulous environmental monitoring to ensure a controlled, low-contamination workspace.

- Multifaceted Expertise: The company’s versatility extends across various industries, such as medical devices, pharmaceuticals, and electronics. Their experience allows them to cater to diverse clean room requirements with finesse.

- Comprehensive Solutions: From injection molding and assembly to packaging and validation, Precision Group offers holistic clean room services. This all-encompassing approach streamlines the production process, reduces waste, and maintains the highest product quality standards.

- Quality Assurance: Precision Group Tooling and Molding’s commitment to quality management and compliance with industry regulations guarantees the delivery of top-tier products with consistency.

Conclusion

Clean room efficiency stands as a cornerstone in modern manufacturing, ensuring product quality and waste reduction. Precision Group Tooling and Molding, with its Clean Room Class 8 Certified Facility, exemplifies a key player in this field, setting the standard for others to follow. Their dedication to innovation, quality, and regulatory compliance makes them a trusted partner in optimizing production processes, reducing waste, and delivering exceptional products. By harnessing the power of clean room technology, Precision Group Tooling and Molding is making a lasting impact on industries, helping them improve their manufacturing operations and reduce their environmental footprint.