Mastering Cleanroom Molding: A Comprehensive Guide by Precision Group

Introduction

In the world of manufacturing, precision and quality are non-negotiable. Cleanroom molding stands as a testament to this commitment, ensuring the production of high-quality components across various industries. Among the pioneers in this domain, the Precision Group has set a gold standard in cleanroom molding. Before delving into the intricacies of this specialized manufacturing process, let’s understand what cleanroom molding is and what you need to know before stepping into this realm.

Understanding Cleanroom Molding

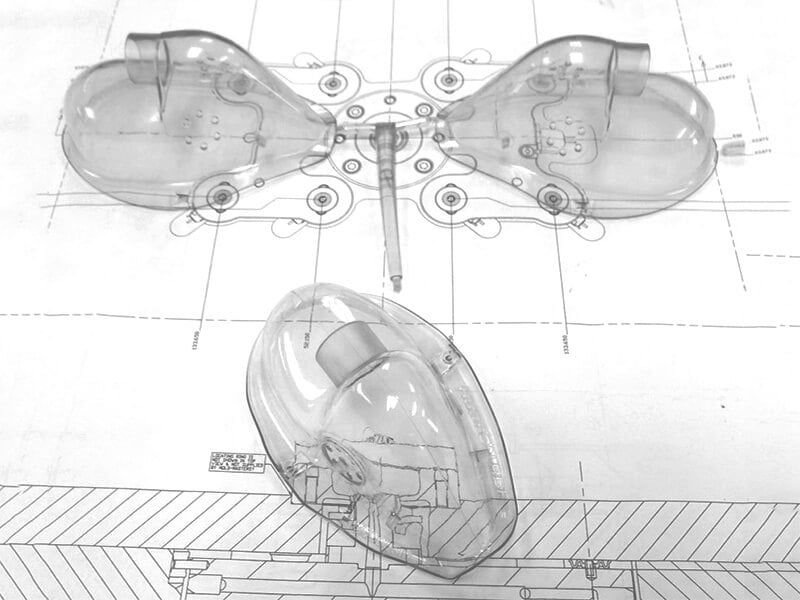

Cleanroom molding isn’t just about producing parts; it’s a meticulous process conducted in a controlled environment to ensure minimal contamination. It involves the creation of components in an environment where air quality, temperature, humidity, and other variables are rigorously regulated. This controlled setting drastically reduces the risk of imperfections and enhances product consistency, making it ideal for industries like medical devices, pharmaceuticals, aerospace, and electronics.

Precision Group: Leading the Cleanroom Molding Frontier

Enter the Precision Group, a frontrunner in cleanroom molding technologies. Their expertise lies not only in manufacturing but also in optimizing the entire production process. With state-of-the-art facilities and a dedicated team, Precision Group ensures that every product meets stringent quality standards.

What You Need To Know Before Manufacturing

- Regulatory Compliance: Industries reliant on cleanroom molding demand strict adherence to regulations. Precision Group’s expertise lies in navigating these regulatory landscapes, ensuring that every product complies with industry standards.

- Material Selection: Cleanroom molding often involves working with sensitive materials. Understanding the compatibility between materials and the cleanroom environment is crucial to prevent contamination and maintain product integrity.

- Design for Manufacturability: Precision Group offers invaluable insights during the design phase. Their expertise helps in creating components that are not only functional but also optimized for cleanroom molding processes.

- Quality Assurance: Maintaining quality throughout the manufacturing process is paramount. Precision Group integrates robust quality checks at every stage to guarantee the consistency and reliability of the final product.

- Cost-Efficiency: While ensuring top-notch quality, Precision Group also focuses on cost-effectiveness. Their optimized processes minimize waste and maximize efficiency without compromising on quality.

Benefits of Cleanroom Molding by Precision Group

- Enhanced Product Quality: The controlled environment ensures fewer defects, leading to higher quality components.

- Consistency and Reliability: Each product meets stringent standards, ensuring reliability in performance.

- Regulatory Compliance: Precision Group’s expertise ensures that products adhere to industry regulations, easing market entry.

- Customization and Flexibility: Tailored solutions are offered to meet specific client requirements without compromising on quality.

Conclusion

Cleanroom molding, championed by the Precision Group, represents a pinnacle of precision manufacturing. Its applications span across industries where quality and precision are non-negotiable. Before venturing into cleanroom molding, understanding its nuances and partnering with experts like Precision Group can make a world of difference in ensuring top-tier products that meet the highest standards of quality and reliability.