Precision Group Tooling and Molding: Transforming Designs into Molding-Ready Parts

Introduction

In the realm of manufacturing, the journey from a brilliant design concept to a tangible, production-ready part can be fraught with challenges. One of the critical junctures in this process lies in translating intricate designs into molding-ready parts. This is where Precision Group Tooling and Molding steps in, wielding expertise honed by a specialized engineering team proficient in CAM/CAD design.

At Precision Group, the focus extends beyond mere manufacturing; it’s about orchestrating a symphony of precision, innovation, and seamless execution to transform design dreams into tangible realities. Often, designs arrive without considering the intricate necessities and constraints imposed by the molding process. This is where the magic happens – the team’s proficiency in CAM/CAD design becomes the pivot around which design aspirations and molding standards harmoniously converge

Bridging Design Aspirations and Molding Standards

Designing a product without considering molding standard necessities might seem like a hurdle, but with Precision Group, it’s an opportunity to showcase their prowess. The specialized engineering team diligently works to dissect, analyze, and transform intricate designs into molding-compatible blueprints. Their proficiency lies not just in understanding designs but in envisioning how these designs can seamlessly align with the prerequisites of the molding process.

Unveiling the Power of CAM/CAD Design

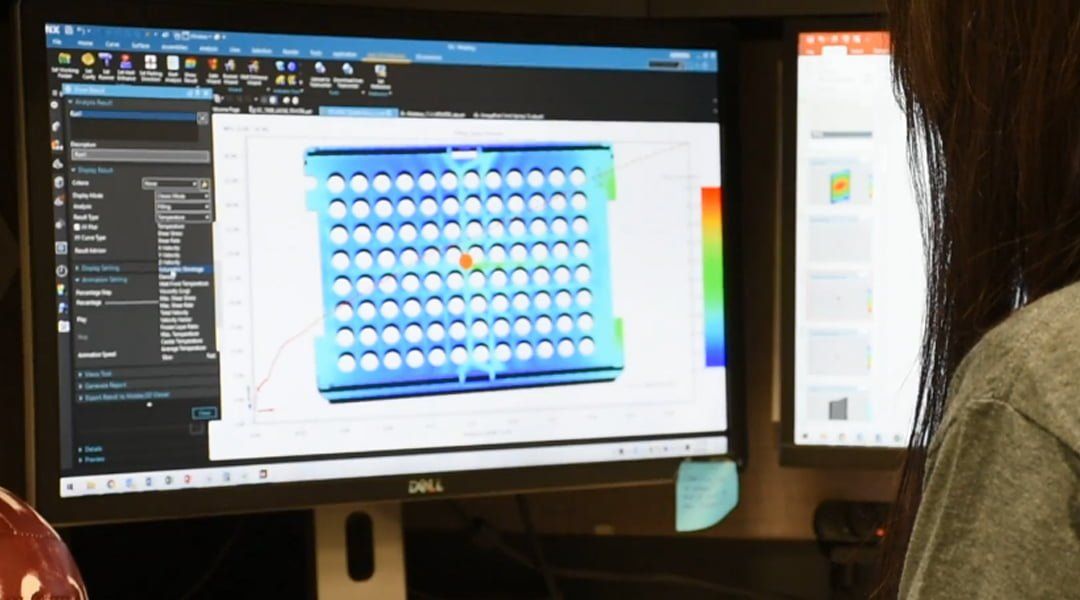

Central to Precision Group’s success is their adeptness in Computer-Aided Manufacturing (CAM) and Computer-Aided Design (CAD). These technologies serve as their artistic canvas, where each stroke of precision and intricacy is carefully etched to bring designs to life. By leveraging the power of these cutting-edge tools, the team crafts intricate pathways, ensuring that the design metamorphoses into a molding-friendly blueprint without compromising its essence.

Collaborative Expertise Driving Innovation

Collaboration is the cornerstone of Precision Group’s modus operandi. The engineering team operates as a collaborative force, bridging the gap between design ingenuity and molding requirements. Their expertise doesn’t just lie in designing; it extends to consultation, working hand-in-hand with clients to understand their vision while guiding them through the intricacies of molding standards.

Precision Group: Transforming Visions into Realities

The journey from design to a final product is a testament to Precision Group’s commitment to excellence. By harnessing the synergy between cutting-edge technology, specialized expertise, and a collaborative approach, they transform intricate designs into molding-ready parts that retain the essence of the initial vision.

Conclusion

Precision Group Tooling and Molding stands as a beacon in the realm of manufacturing, where intricate designs find their perfect harmony with molding standards. Their engineering team’s specialized proficiency in CAM/CAD design doesn’t just bridge gaps; it creates an amalgamation of innovation and precision, turning design aspirations into tangible, molding-ready masterpieces.

For those seeking to transcend design boundaries and venture into the realm of flawless molding, Precision Group emerges as the guiding light, ensuring that every design dream finds its molding-ready reality.