The Rise of Nearshoring: Exploring the USA-Mexico Manufacturing Partnership and Precision Group Tooling and Molding’s Approach

Introduction:

In the ever-evolving world of global manufacturing, businesses are increasingly turning to nearshoring to enhance their competitive edge. The proximity and collaborative advantages offered by neighboring countries have made the USA and Mexico an attractive duo for manufacturing partnerships. This article delves into the rise of nearshoring, focusing on the manufacturing partnership between the two countries, and how Precision Group Tooling and Molding has successfully approached operating in both.

The USA-Mexico Manufacturing Partnership:

The USA and Mexico have a long history of economic cooperation, exemplified by the North American Free Trade Agreement (NAFTA) and its successor, the United States-Mexico-Canada Agreement (USMCA). These agreements have paved the way for the development of a strong manufacturing partnership. Here’s why this partnership has become increasingly popular:

- Proximity: The geographical closeness of the two countries reduces shipping times and costs, enabling just-in-time production and faster response to market demands.

- Cost Savings: Labor and operational costs in Mexico are generally lower than in the USA, making nearshoring a cost-effective choice.

- Skilled Workforce: Mexico boasts a skilled labor force, especially in manufacturing and engineering, making it an ideal partner for US businesses.

Precision Group Tooling and Molding’s Approach:

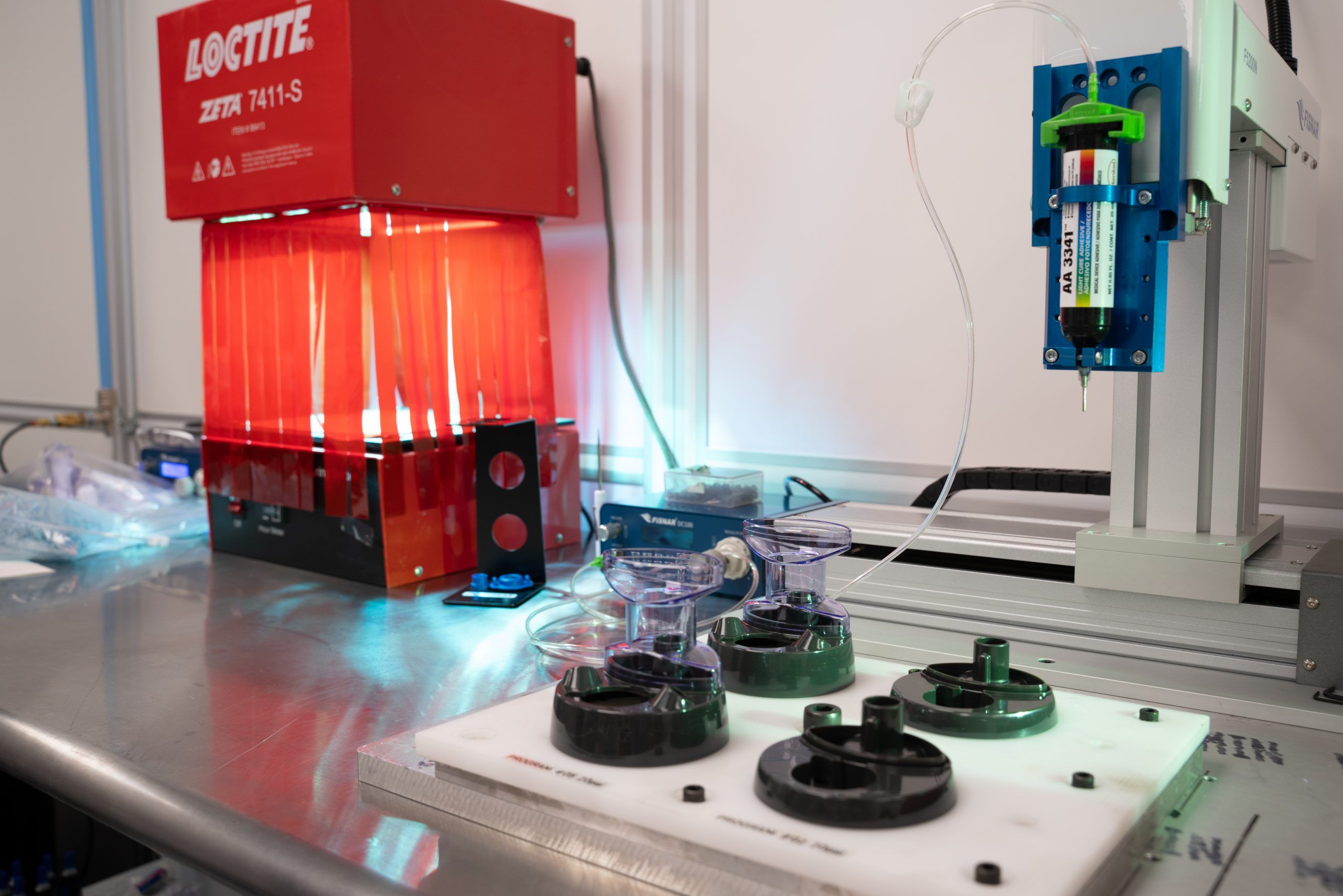

One company that has harnessed the potential of the USA-Mexico manufacturing partnership is Precision Group Tooling and Molding, a leader in injection molding and precision tooling. Here’s how they’ve approached operating in both countries:

- Dual Facilities: Precision Group maintains manufacturing facilities in both the USA and Mexico. This strategic positioning allows them to maximize the benefits of nearshoring.

- Supply Chain Optimization: With facilities near each other, Precision Group can seamlessly coordinate their supply chain, reducing lead times and ensuring just-in-time delivery.

- Quality Control: Precision Group’s commitment to maintaining high-quality standards is upheld in both locations. They’ve implemented rigorous quality control processes and inspection protocols to ensure consistency across borders.

- Skilled Workforce: Leveraging the skilled Mexican workforce, Precision Group has been able to access a talent pool adept at precision manufacturing, which is crucial for their products.

- Compliance and Regulations: By staying up to date with international trade regulations and customs requirements, Precision Group has successfully navigated the legal and compliance aspects of nearshoring.

Conclusion:

The rise of nearshoring between the USA and Mexico has brought about a new era of manufacturing collaboration, offering substantial advantages to businesses in both countries. Companies like Precision Group Tooling and Molding serve as prime examples of how to approach and excel in this dynamic manufacturing landscape.

As the world continues to change and adapt, the USA-Mexico manufacturing partnership is poised to remain a vital component of global supply chains. It’s a testament to the power of proximity, collaboration, and effective business strategies, as exemplified by companies like Precision Group Tooling and Molding, that can lead to success in nearshoring endeavors.