Plastic injection in San Antonio has multiple and varied quality control procedures, which must be guaranteed from beginning to end by the companies dedicated to it.

Do not forget that plastic is widely used in different industries thanks to its huge potential for a total optimization of resources, time and results.

However, something we must contemplate from the first moment is just this: what type of industry or product made by plastic injection needs to be manufactured.

From this first analysis, your company supplier of plastic injection molds or objects must ensure that the quality of the transformation of this raw material remains unalterable throughout the entire process and stages.

This is why, today we are going to talk about the main quality control actions in plastic injection in San Antonio since it is important to have this information, regardless the industry to which your product belongs, to guarantee its quality internationally.

What quality control policies should the industries with plastic injection products have?

Working with plastic as raw material requires certainty and guarantee of all production processes, so that they comply with the plastic injection standards in the world.

From automobiles, inputs and medical tools, spaceships, to everyday commercial items which use this versatile material, must be manufactured in accordance to the standards and certifications established for plastic injection molding in San Antonio and internationally.

There are tons of plastic applications in the market, but we can emphasize 6 industries that use these pieces made by injection in their daily operations:

- Medical

- Automotive

- Science and technology

- Electronics

- Energy

- Oil Industry

- Consumer Industry

As we can observe, the multiplicity of items of each industry must be guaranteed by the quality control of the production of plastic objects manufactured by the injection molding method.

This way, it is necessary that your plastic injection supplier in San Antonio has the infrastructure, human and technological, so that your company quality is guaranteed by the standards of plastic production in the world.

Each industry must obey the international quality certifications that are adjusted to the applications and contexts of the production of plastic injection molded parts.

What certifications are key for plastic injection in San Antonio?

Many are the certifications that ensure the plastic production. In this article we will talk about two of the most important: ISO 13485:2006 and ISO 9001:2015.

We will be addressing key aspects of each one so you can keep them in mind, managing the entire operation together with the help of a professional plastic injection molding supplier working to these standards and with certified facilities.

1.- ISO 13485:2016 Certification

This certification is the one that takes care of everything concerning the plastic injection processes in the medical industry, guaranteeing that the production complies with the requirements to not jeopardize human health.

Between the many procedures that this certification endorses, the following qualifications and tests highlight, these are performed on the product, producer and raw material:

- IQ or installation qualification

- OQ or machine operation qualification

- PQ or product performance qualification

These qualifications are written according to the Food and Drug Administration standards (FDA). Keeping this in mind, in Precision Group we have a master record of the mold and product, as well as a record of the printed or produced device certification, also according to FDA specifications, which gives us the ability to create plastic injection products for the medical industry.

This way we can produce bone and tissue repair technology, oxygen masks and vacuum pumps with the quality required by international standards.

2.- ISO 9001:2015 Certification

This certification is the one that endorse the plastic injection production in the other 6 industries that we mentioned above (automotive, science and technology, electronics, energy, oil industry and consumer industry)

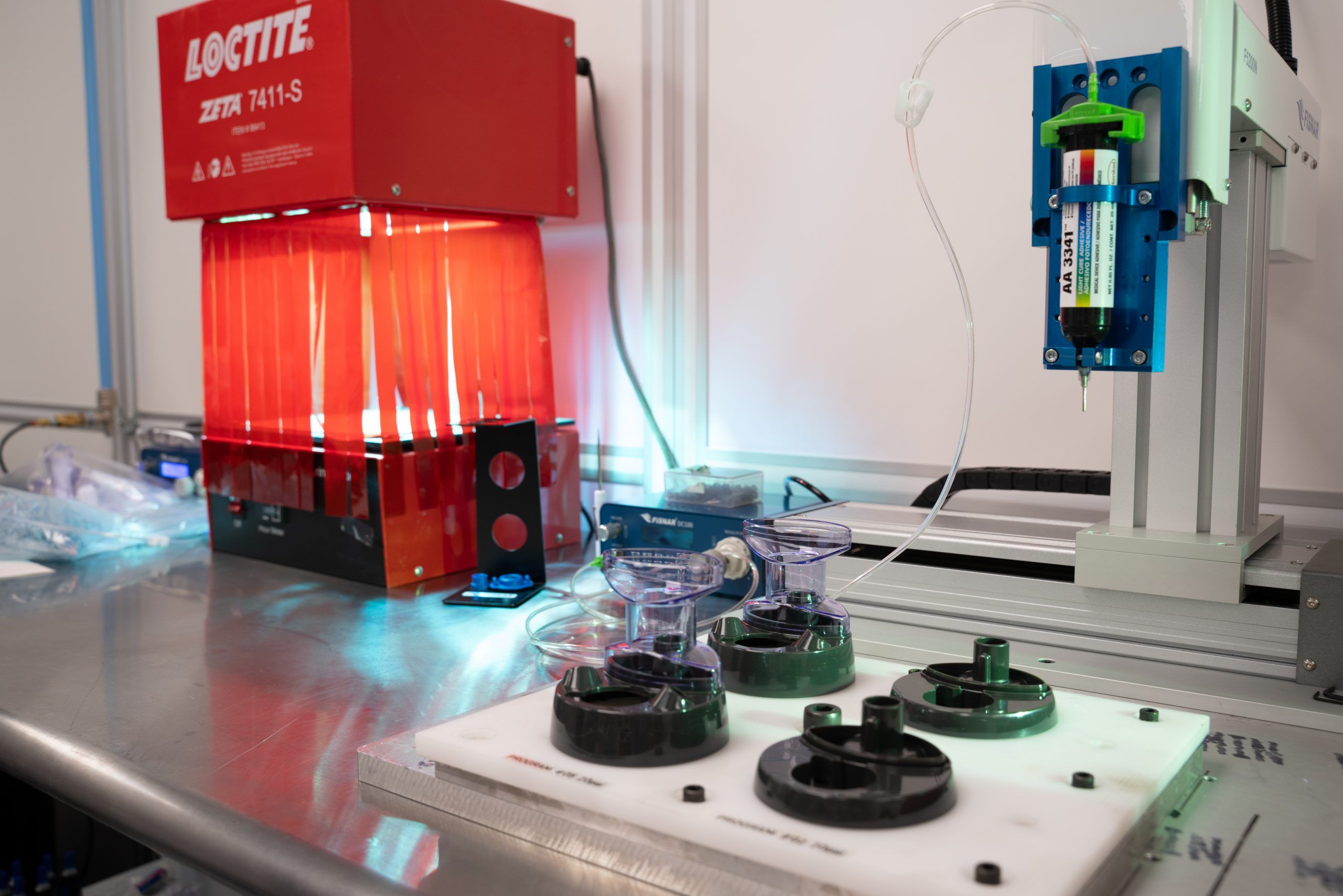

In this area, a key element about this certification are the machinery qualifications CMM (Coordinate Measuring Machine) which, as its name suggests, is a machine that measures coordinates responsable of the high precision in all the pieces and parts.

This is based on a program design which generates an automatic repetition, where the piece is placed on the machine’s calibrated surface, verifying the specific coordinates of each project or client, and corroborating in every moment the piece with the specific requirements.

This way the quality area carries out a special calibration where all the pieces are certified and validated by third-party agents to ensure the established standard.

In turn, the CMM technology allows the use of reverse engineering. For example, if a client requires digitizing an object, the part in question can be recreated point by point. Afterwards is created a digital file that is used with the purpose to create molds and new production pieces.

On the other hand, many processes of these certifications are carried out in a metrology lab, with specialized tools of optic comparison and microscopes.

Other factors to consider

On the other hand, in the automotive and aerospace industry case, it is advisable to perform an analysis or FMEA (Failure Modes and Effects Analysis). Another essential analysis in the automotive industry and its molding injection production is PPAP o Part Approval Process.

These studies allow us to test how the piece will work in the design and its functions, before it is manufactured entirely.

Do you have any questions about the quality control for your plastic parts? Schedule an appointment with Precision Group, our advisors will assist you.

We work with a customer centric approach that creates solutions for our clients from all types of industries around the world, helping their product to have the quality that their plastic endorses.

Share this article on your social media and with your colleagues, acquaintances or people interested in the plastic world. See you next time!