Revolutionizing Tooling: The Precision Group’s Approach to Prototyping Tools

Introduction.

In the fast-paced world of the tooling industry, innovation is the key to staying ahead. Prototyping tools have become indispensable for manufacturers aiming to create cutting-edge solutions that meet the ever-evolving demands of various industries. Among the frontrunners in this space is the Precision Group, a trailblazing company that has redefined the approach to prototyping tools, setting new standards for precision, efficiency, and excellence.

The Significance of Prototyping Tools.

Prototyping tools play a pivotal role in the tooling industry by providing a tangible representation of a product before mass production begins. This process allows manufacturers to test and refine designs, identify potential issues, and make necessary adjustments, ultimately ensuring the final product meets the desired specifications.

The Precision Group’s Innovative Approach.

The Precision Group has gained prominence for its forward-thinking approach to prototyping tools, incorporating cutting-edge technologies and methodologies to enhance precision and efficiency. Here are some key aspects of their innovative approach:

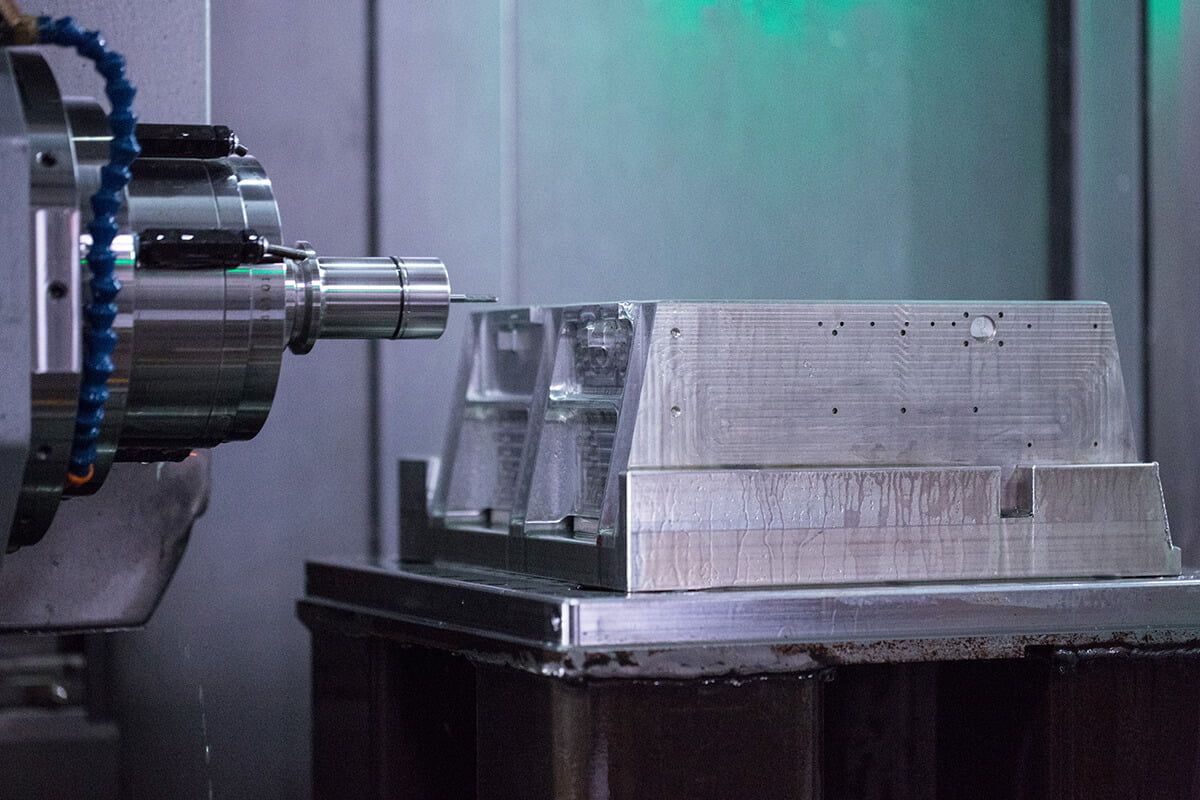

- Advanced Materials and Techniques: The Precision Group employs state-of-the-art materials and techniques in prototyping to achieve unparalleled precision. High-performance alloys, advanced polymers, and additive manufacturing technologies are seamlessly integrated into the prototyping process, ensuring the end result mirrors the final product’s quality and functionality.

- Digital Twin Technology: Leveraging digital twin technology, the Precision Group creates virtual replicas of the tooling designs. This allows for thorough simulations and analyses, enabling engineers to identify potential flaws or areas for improvement. The synergy between digital models and physical prototypes streamlines the development process, reducing time-to-market and minimizing costly errors.

- Iterative Design and Rapid Prototyping: The Precision Group embraces an iterative design philosophy, where multiple prototypes are rapidly developed and tested. This agile approach facilitates quick iterations, allowing for on-the-fly adjustments and improvements. This not only accelerates the product development cycle but also enhances the overall quality of the final tooling solutions.

- Collaborative Development Process: The Precision Group fosters a collaborative development process, working closely with clients to understand their unique requirements and challenges. This partnership ensures that the prototyping tools are tailored to meet specific industry needs, fostering innovation and addressing evolving market demands.

- Environmental Sustainability: Recognizing the importance of sustainability, the Precision Group incorporates eco-friendly materials and processes in their prototyping efforts. This commitment to environmental responsibility aligns with the growing global focus on sustainable manufacturing practices.

Conclusion.

In the dynamic landscape of the tooling industry, the Precision Group’s approach to prototyping tools stands out as a beacon of innovation and excellence. By combining advanced materials, digital twin technology, iterative design, collaborative development, and environmental sustainability, the Precision Group continues to redefine the standards for precision in the tooling industry. As manufacturers worldwide seek to stay at the forefront of innovation, the Precision Group’s approach to prototyping tools serves as an inspiring model for the future of the industry.