Mastering Complex Geometry Machining: Precision Group’s Path to Unrivaled Tooling Tolerances

Introduction

In the realm of manufacturing, the pursuit of precision and perfection in tooling has always been an enduring quest. The ability to achieve tight tolerances in complex geometries has long been a challenge, requiring a delicate blend of cutting-edge technology, expertise, and unwavering dedication. Among the pioneers in this field stands the formidable entity known as Precision Group, renowned for its exceptional mastery in crafting tools with micron-level precision.

Understanding Complex Geometry Machining

Complex geometry machining involves the fabrication of intricate components and tooling shapes that deviate from traditional, straightforward designs. These intricate geometries often demand a level of precision that pushes the boundaries of conventional manufacturing methods. To create these complex shapes accurately, a combination of advanced machinery, meticulous planning, and unparalleled skill is essential.

Precision Group’s Cutting-Edge Approach

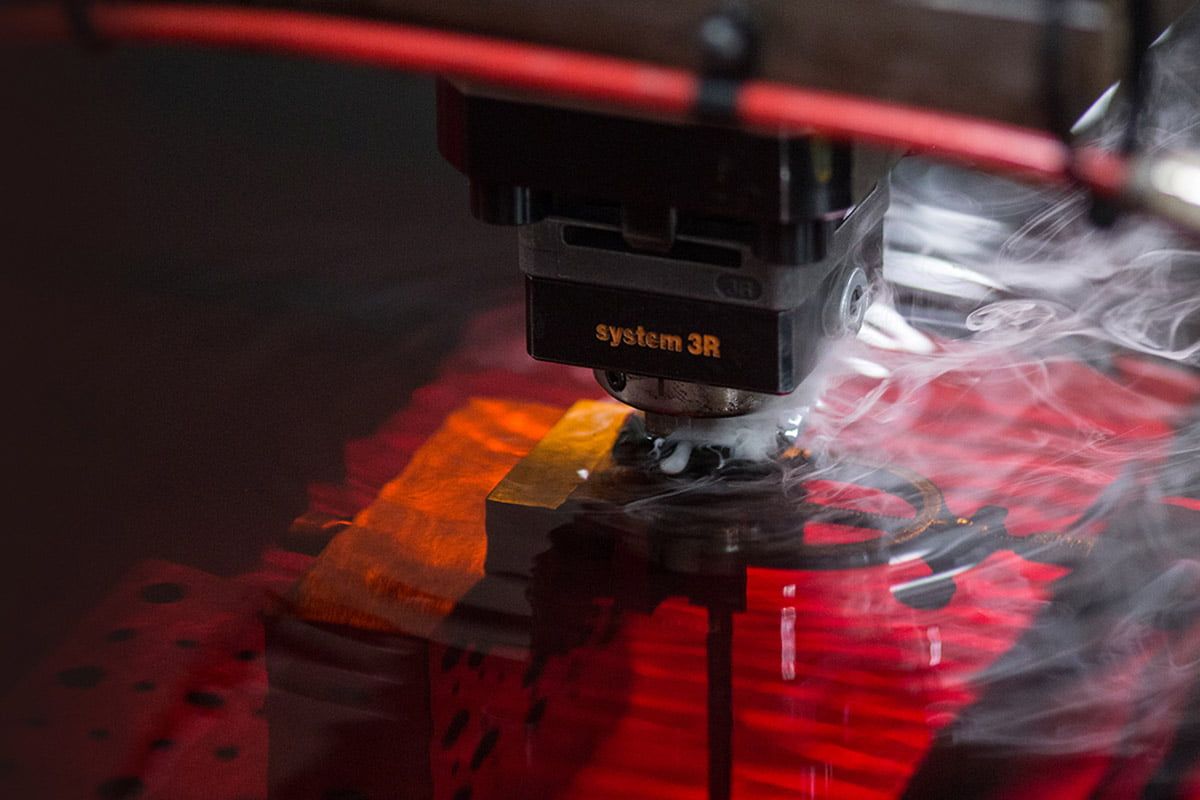

At the heart of Precision Group’s success lies a sophisticated array of cutting-edge machining tools. Computer Numerical Control (CNC) machines, EDM (Electrical Discharge Machining) equipment, and high-precision grinding machinery form the backbone of their operations. However, it’s not just about having the right tools—it’s about the expertise and innovative strategies applied in their utilization.

- Advanced CAD/CAM Software Integration, Precision Group harnesses the power of state-of-the-art Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. These programs allow their engineers to meticulously plan and simulate the entire machining process, optimizing tool paths and ensuring every minute detail is accounted for before the physical production even begins.

- Multi-Axis Machining Capabilities, One of the hallmarks of Precision Group’s prowess is its proficiency in multi-axis machining. By utilizing machines capable of simultaneous movement along multiple axes, they achieve unparalleled precision in the creation of complex geometries. This versatility enables the fabrication of intricate tooling shapes with exceptional accuracy.

- Adaptive Machining Strategies, The team at Precision Group doesn’t shy away from experimentation and innovation. They continuously refine their machining strategies, adopting adaptive techniques that optimize the manufacturing process for each unique geometry. This agile approach allows them to overcome challenges that arise from the inherent complexities of the designs.

- Rigorous Quality Control Measures, Precision is not just a name; it’s a commitment reflected in their stringent quality control measures. Through a series of meticulous inspections, including 3D metrology and high-precision measurement tools, they ensure that every component meets or exceeds the specified tolerances.

The Quest for Unmatched Tolerances

The pursuit of high tolerances in tooling at Precision Group is not merely a goal; it’s a relentless pursuit of excellence. They understand that achieving micron-level precision isn’t a one-time feat but an ongoing journey that requires continuous improvement and innovation.

Case Study: Exceeding Expectations

A recent project undertaken by Precision Group involved the creation of a specialized tool for aerospace components. The intricate design necessitated tolerances within incredibly tight margins. Leveraging their expertise and cutting-edge machinery, they not only met but surpassed the client’s expectations, delivering a tool that set a new benchmark for precision in the industry.

Conclusion

In the realm of complex geometry machining, Precision Group stands as a beacon of innovation and precision. Through their amalgamation of advanced technology, unwavering commitment to excellence, and a team of skilled artisans, they continue to redefine the boundaries of what’s achievable in the realm of tooling tolerances. Their journey isn’t just about shaping metal; it’s about sculpting a legacy of unparalleled precision that resonates throughout the manufacturing industry.