Precision Group’s Expertise: Navigating Engineering Changes in Existing Molds

Introduction

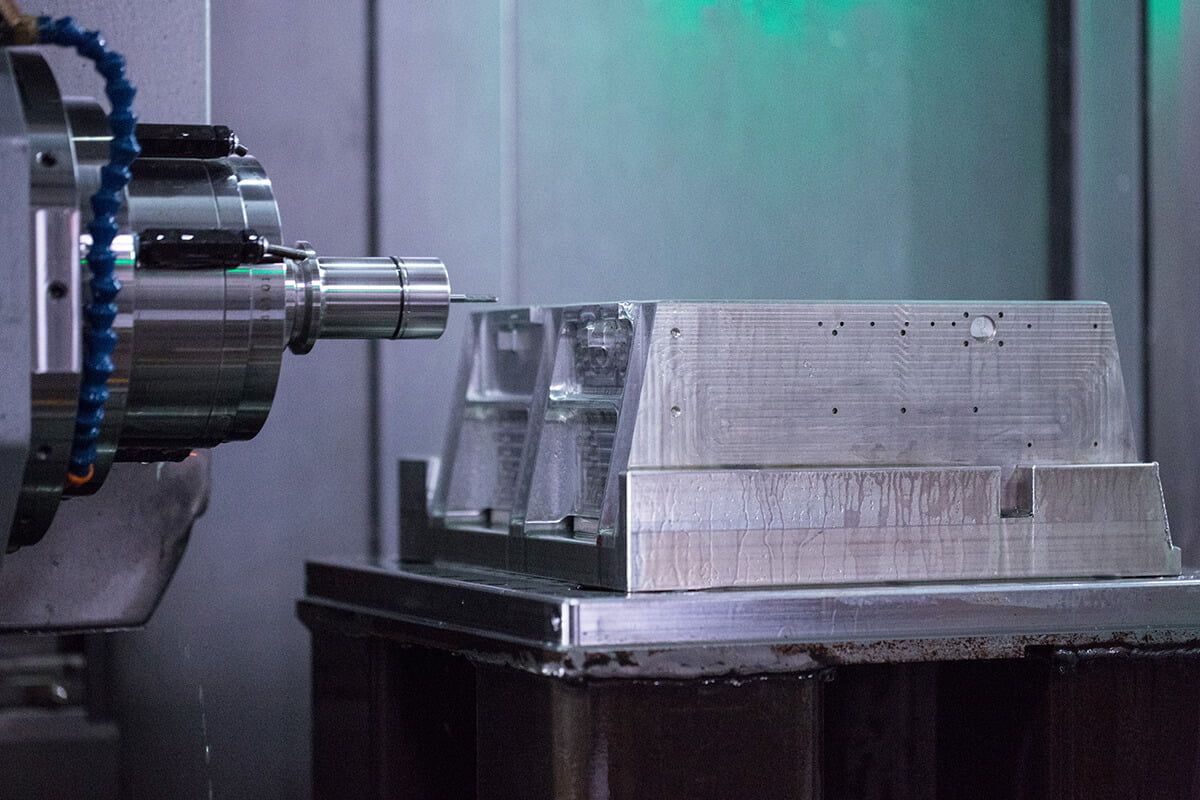

In the intricate world of manufacturing, precision is the backbone of success. When it comes to existing molds, incorporating engineering changes poses a unique set of challenges. In this blog post, we will explore the intricacies of modifying existing molds and how Precision Group, with its top-notch expertise, skillfully manages these challenges to ensure seamless transitions and optimal outcomes.

The Challenge

Modifying an existing mold requires a delicate balance between precision and efficiency. Unlike creating a new mold from scratch, where one has the luxury of a clean slate, engineering changes in existing molds demand a deep understanding of the current design, material properties, and the potential impact on ongoing production.

- Compatibility Concerns: Existing molds may have been designed with specific materials and processes in mind. Introducing engineering changes brings forth compatibility concerns, as alterations must seamlessly integrate with the existing mold without compromising its structural integrity or performance.

- Risk of Unforeseen Consequences: Each modification in an existing mold can have a domino effect on the entire manufacturing process. Precision is crucial to avoid unforeseen consequences such as defects, deviations in product quality, or disruptions in production efficiency.

- Adaptation to Varied Technologies: Over time, technological advancements may have occurred in the manufacturing industry. Precision Group faces the challenge of adapting existing molds to incorporate the latest technologies, ensuring they remain competitive in a rapidly evolving landscape.

How Precision Group Manages the Challenge

- Thorough Mold Assessment: Precision Group starts by conducting a comprehensive assessment of the existing mold. This includes a detailed analysis of its design, material composition, and historical performance. This thorough understanding forms the basis for planning and executing engineering changes.

- Advanced Simulation and Modeling: Leveraging cutting-edge simulation and modeling tools, Precision Group meticulously analyzes the proposed engineering changes. This enables them to predict potential challenges, simulate different scenarios, and optimize modifications before implementation, minimizing the risk of unexpected issues.

- Tailored Solutions for Compatibility: Precision Group understands that every existing mold is unique. Their top expertise lies in crafting tailored solutions that seamlessly integrate with the current mold design, ensuring compatibility and mitigating any adverse effects on production.

- Collaboration with Clients: Communication is key in navigating engineering changes in existing molds. Precision Group collaborates closely with clients to understand their specific requirements, address concerns, and provide transparent insights into the proposed modifications, fostering a partnership that ensures successful outcomes.

- Continuous Training and Adaptation: Precision Group invests in continuous training for its team, ensuring that they stay updated on the latest technologies and industry best practices. This commitment to ongoing education enables them to adapt swiftly to new challenges and implement innovative solutions in engineering changes.

Conclusion

Precision Group stands as a beacon of excellence in managing the challenges associated with engineering changes in existing molds. Through a meticulous approach, advanced technology utilization, and a commitment to client collaboration, they navigate the complexities of modifying existing molds with unparalleled expertise. As the manufacturing landscape continues to evolve, Precision Group remains at the forefront, consistently delivering seamless and efficient solutions for engineering changes in existing molds.