Unveiling the Magic: How Precision Group Masters Reverse Engineering in Tooling

Introduction

In the realm of manufacturing, precision is paramount. From aerospace components to automotive parts, every millimeter matters. Yet, what happens when the blueprint is missing or outdated? This is where reverse engineering swoops in as the unsung hero of the industry. And when it comes to mastering this art, Precision Group stands at the forefront, showcasing innovation and expertise in every project they undertake.

In Essence

Reverse engineering is the process of deconstructing a product to understand its design, function, and components. It’s akin to solving a complex puzzle where each piece holds the key to unlocking the whole picture. However, the real challenge lies not just in unraveling the mystery but in doing so with precision and efficiency. This is precisely where Precision Group excels.

At Precision Group, reverse engineering is not merely a task; it’s a craft refined over years of experience and dedication to perfection. Their approach is multifaceted, blending cutting-edge technology with a deep understanding of materials, processes, and client needs.

State-of-the-Art Scanning Technology

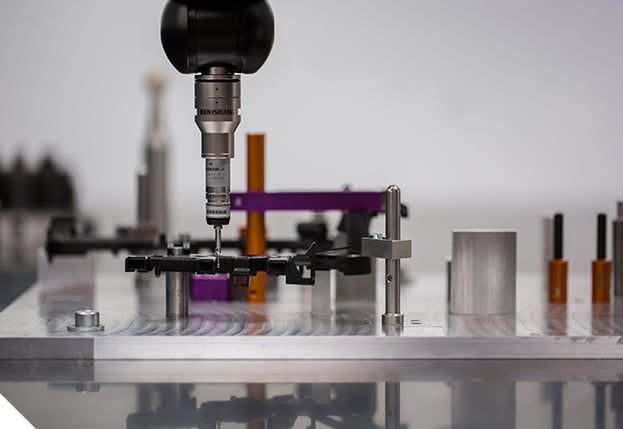

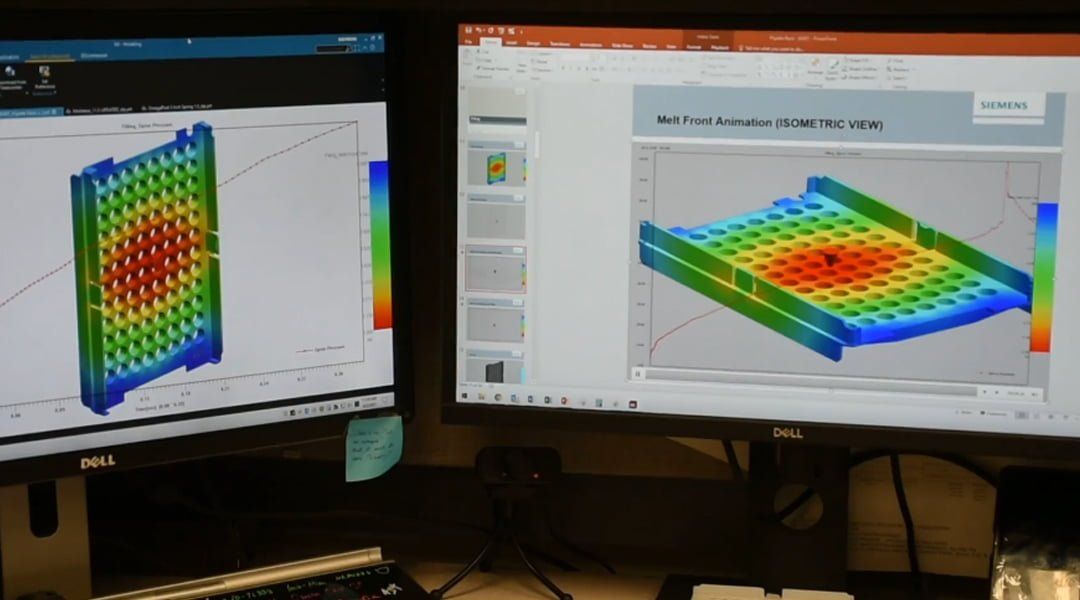

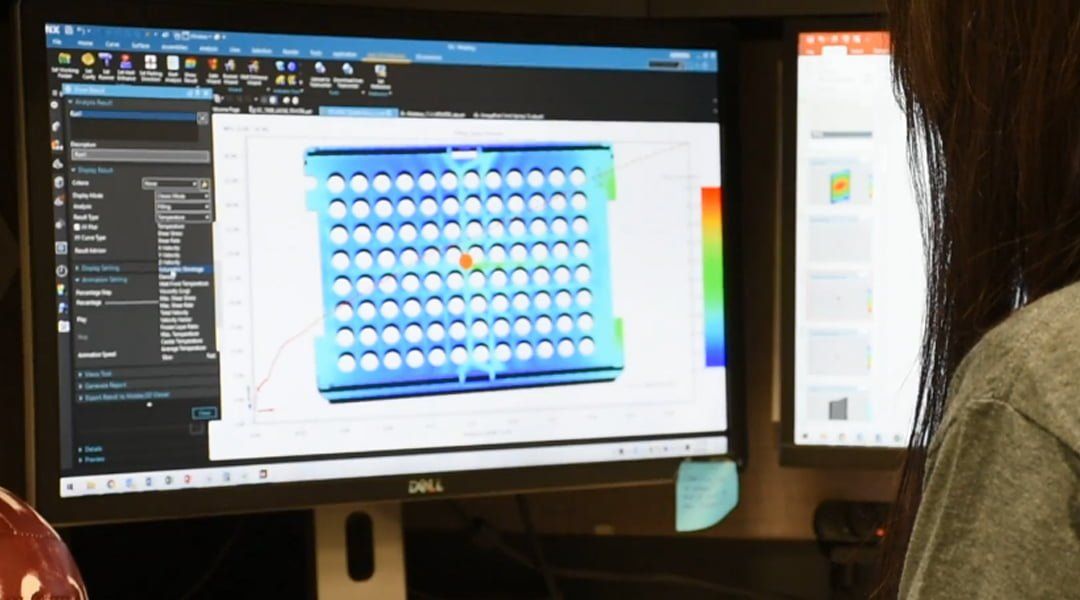

One of the cornerstones of Precision Group’s success in reverse engineering lies in its technology. Utilizing advanced 3D scanning equipment, they meticulously capture every detail of the object under scrutiny. Whether it’s a complex machine part or a delicate mold, nothing escapes the keen eye of their scanners. This digital replica serves as the foundation for the entire reverse engineering process, ensuring accuracy down to the micron.

But scanning is just the beginning. Precision Group goes beyond surface-level data collection, delving deep into the intricacies of design and functionality. Their team of engineers, armed with decades of collective expertise, meticulously analyze the scanned data, deciphering the nuances of each component. It’s a blend of art and science, where creativity meets precision engineering.

One of the key challenges in reverse engineering lies in interpreting the scanned data accurately. Here, Precision Group’s commitment to excellence shines through. Through rigorous quality control measures and iterative refinement, they ensure that the reconstructed model faithfully represents the original object. This attention to detail not only ensures dimensional accuracy but also guarantees compatibility and functionality—a crucial aspect in industries where every component plays a vital role in the larger system.

Moreover, Precision Group’s mastery of materials adds another layer of sophistication to their reverse engineering endeavors. Whether it’s metal alloys, polymers, or composites, they possess the expertise to select the optimal materials for the task at hand. This not only enhances the performance of the final product but also ensures longevity and reliability—a testament to their unwavering commitment to quality.

Perhaps the most remarkable aspect of Precision Group’s approach to reverse engineering is their ability to turn challenges into opportunities. In an industry where innovation is the lifeblood of progress, they embrace complexity as a catalyst for growth. Whether it’s reverse engineering legacy components for modernization or reimagining existing designs for improved efficiency, they thrive on pushing the boundaries of what’s possible.

Conclusion

Reverse engineering is not just a technical process; it’s a journey of discovery and innovation. And in this journey, Precision Group stands as a beacon of excellence, showcasing the transformative power of precision engineering and ingenuity. With their unmatched expertise, cutting-edge technology, and unwavering dedication to quality, they continue to redefine the possibilities of reverse engineering, shaping the future of manufacturing one meticulously crafted component at a time.