Mastering Precision: The Unveiling of CAM Design in Tooling

Introduction

In the dynamic world of manufacturing, Computer-Aided Manufacturing (CAM) has emerged as a cornerstone for precision engineering and tooling. This transformative technology, when applied with expertise, has the power to revolutionize the tooling industry. In this article, we’ll explore the realm of CAM design and delve into how Precision Group has elevated its tooling solutions through unparalleled mastery of this cutting-edge technique.

Understanding CAM Design

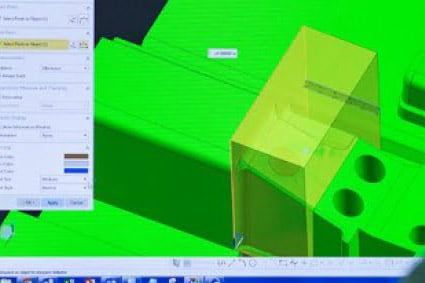

Computer-Aided Manufacturing (CAM) is a technology that utilizes computer software and machinery to automate the manufacturing process. In the tooling industry, CAM design plays a crucial role in translating digital models into physical precision components. It encompasses a wide range of processes, from CNC machining to 3D printing, ensuring accuracy and repeatability in the production of tooling solutions.

Precision Group’s Proficiency in CAM Design

Enter Precision Group, a trailblazer in the tooling industry, renowned for its commitment to excellence and embracing the latest technologies. With a strategic focus on leveraging CAM design, Precision Group has positioned itself as a leader, delivering superior tooling solutions that meet the highest standards of quality and precision.

Key Advantages of CAM Design in Tooling

- Precision Engineering: CAM design allows for the creation of highly precise and intricate tooling components. The digital precision translates seamlessly into physical form, ensuring that the end product meets the exact specifications required by industries ranging from medical to consumer electronics.

- Efficiency and Speed: CAM design automates the manufacturing process, significantly reducing production time. Precision Group’s proficiency in CAM enables streamlined workflows, resulting in quicker turnaround times without compromising on quality.

- Complex Geometries and Customization: The versatility of CAM design empowers tooling engineers to work with complex geometries and create customized components tailored to specific applications. This flexibility is invaluable in industries where tooling requirements are diverse and often unique.

- Cost-Effective Production: By optimizing the manufacturing process, CAM design contributes to cost-effectiveness. Precision Group’s expertise in CAM ensures efficient material usage, reduced waste, and minimized production costs, making their tooling solutions economically viable for a wide range of industries.

Case Studies: Precision Group’s Triumphs in CAM Design

To illustrate Precision Group’s mastery in CAM design, let’s explore a couple of success stories:

Medical Device Manufacturing: Precision Group collaborated with a leading medical device manufacturer to produce intricate and customized tooling components using CAM design. The result was a significant reduction in production time and costs while maintaining the highest standards of precision.

Consumer Electronics: In the competitive world of consumer electronics, Precision Group’s CAM design expertise played a pivotal role in developing tooling solutions for intricate components. This allowed their clients to stay ahead in a rapidly evolving market.

Conclusion

As technology continues to reshape the manufacturing landscape, CAM design stands out as a pivotal force in the tooling industry. Precision Group’s commitment to excellence and mastery of CAM design have positioned them as leaders in delivering precision tooling solutions. By seamlessly integrating digital precision with physical components, Precision Group is at the forefront of shaping the future of tooling through the transformative power of CAM design.