Cold Runner vs. Hot Runner Systems: Choosing Efficiency with Precision Group

Introduction

In the realm of plastic injection molding, the choice between cold runner and hot runner systems remains a critical decision that profoundly impacts efficiency, precision, and overall cost-effectiveness. This decision-making process involves a careful evaluation of multiple factors, and Precision Group stands as a beacon guiding manufacturers through this complex landscape.

Understanding Cold Runner and Hot Runner Systems

Before delving into their advantages and efficiencies, let’s grasp the fundamentals:

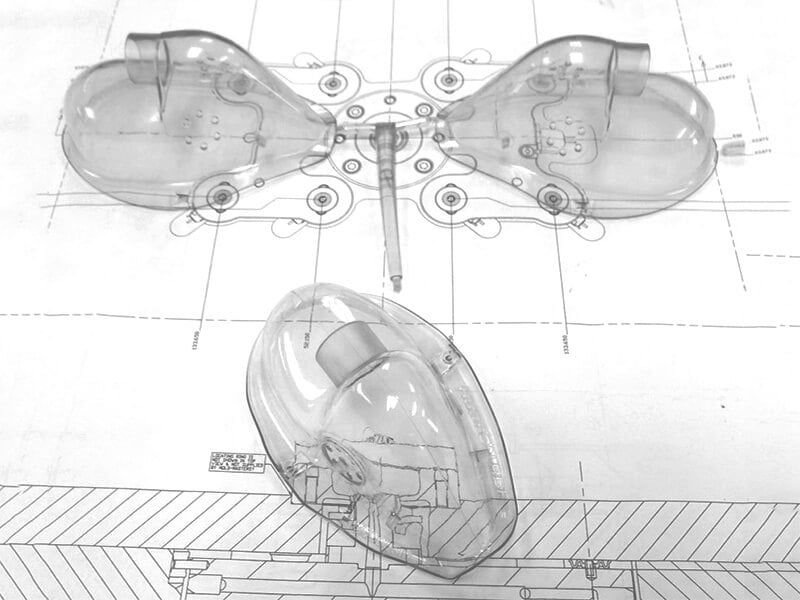

Cold Runner Systems

These are traditional injection molding systems comprising channels (runners) that guide molten plastic from the injection molding machine nozzle to the cavities. The unused plastic in the runners, known as sprues and gates, is typically ejected as waste after solidification.

Hot Runner Systems

These advanced systems feature heated channels that maintain the molten state of plastic, eliminating the need for solidification in the runners. This allows for a more controlled, efficient, and waste-minimized injection molding process.

Efficiency Advantages

- Material Savings: Hot runner systems significantly reduce material wastage by eliminating the need for ejecting solidified plastic in the runners. This reduction translates into cost savings and a more environmentally friendly production process.

- Faster Cycle Times: The continuous flow of molten plastic in hot runner systems eliminates the pauses for solidification and reheating seen in cold runner systems. Consequently, production cycles are faster and more efficient, leading to increased output.

- Reduced Post-Processing: Cold runner systems often necessitate the removal and disposal of solidified runners, adding post-processing steps. Hot runner systems mitigate this need, streamlining the production line and reducing overall processing time.

Precision and Quality

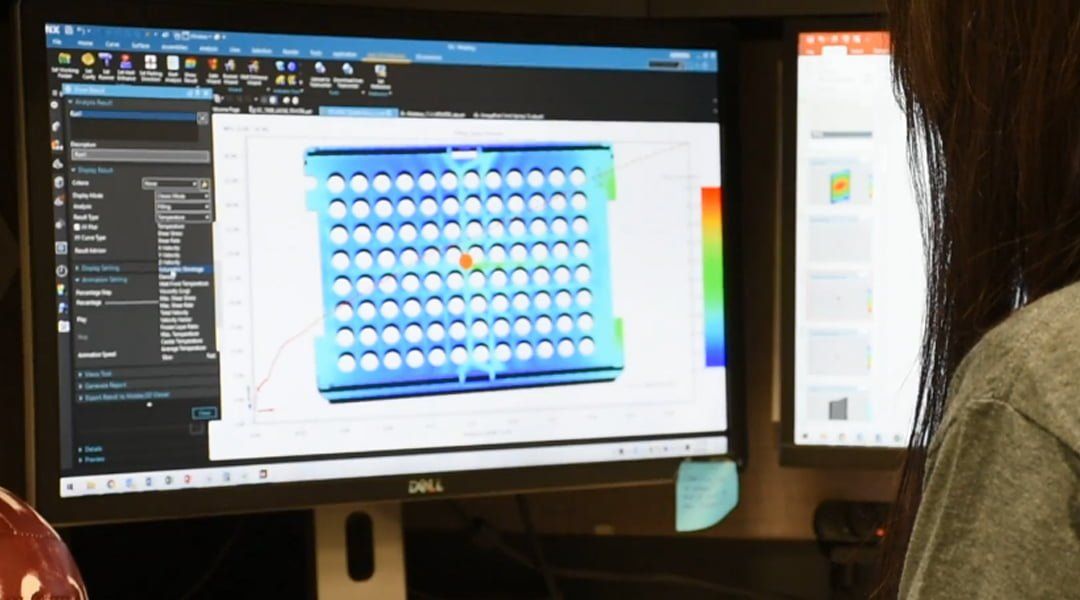

- Enhanced Control: Hot runner systems offer superior control over the injection process, allowing for precise regulation of temperature, flow, and pressure. This control results in better part quality with reduced variations and inconsistencies.

- Lower Risk of Defects: The elimination of runner-related issues such as gate vestiges, weld lines, and variations in cooling temperatures ensures higher-quality finished products from hot runner systems.

- Complex Designs: Hot runner systems facilitate the molding of intricate and complex designs with greater ease due to the precise control over material flow and distribution.

Decision-Making with Precision Group

Precision Group stands out as an industry leader in assisting manufacturers in the selection and optimization of molding processes. Their expertise and consultation services help in:

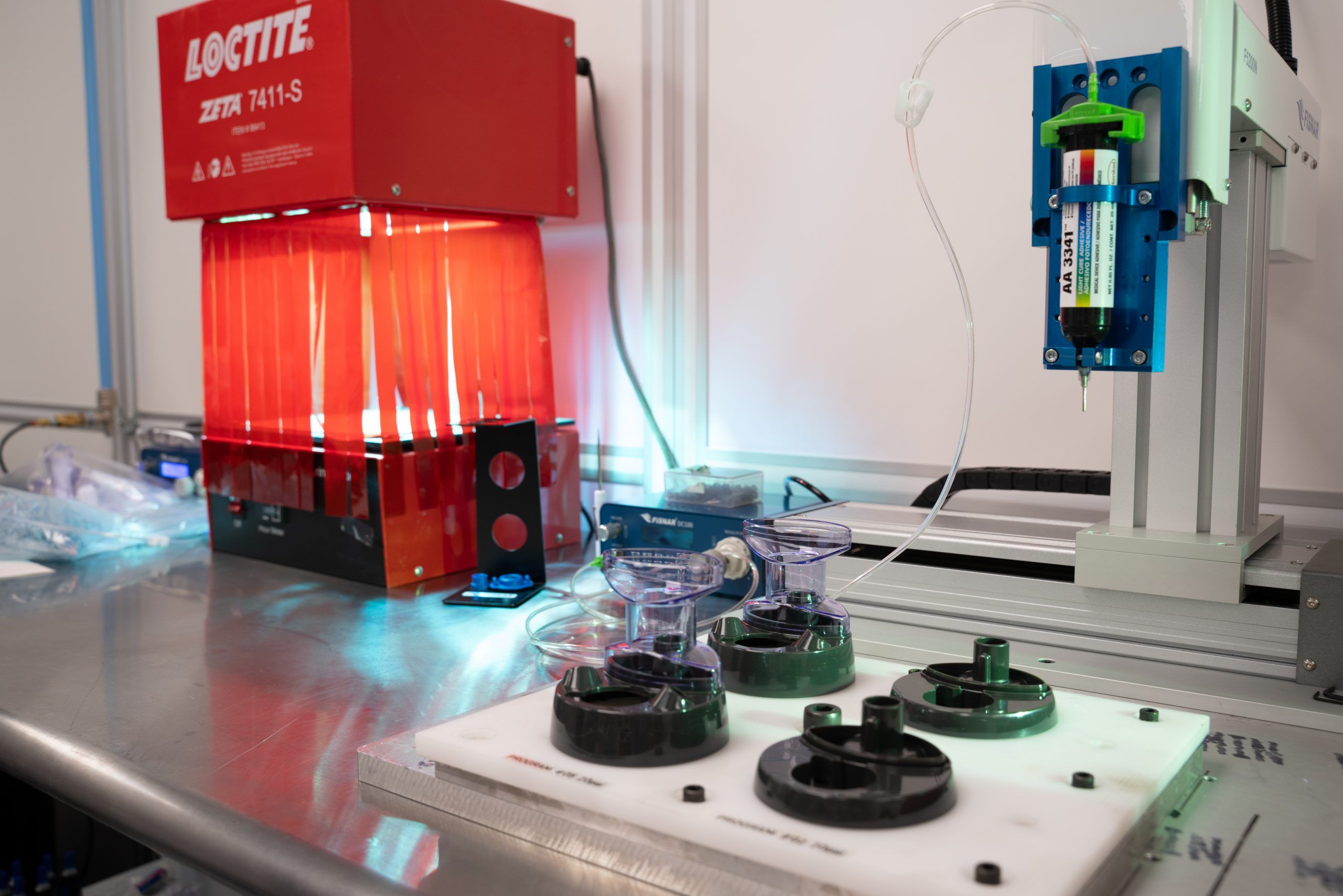

- Assessing Specific Requirements: Understanding the intricacies of your project, including material type, part complexity, production volume, and cost considerations.

- Custom Solutions: Offering tailored recommendations based on your unique requirements, ensuring optimal efficiency, precision, and cost-effectiveness.

- Technology Integration: Implementing cutting-edge hot runner systems and optimizing cold runner designs to maximize efficiency and minimize waste.

Conclusion

While both cold runner and hot runner systems have their merits, Precision Group’s guidance in evaluating the specific needs of your project ensures a well-informed decision. The adoption of hot runner systems often leads to enhanced efficiency, reduced waste, and superior part quality, making it a viable choice for many manufacturers seeking precision and cost-effectiveness in plastic injection molding.

Making the right choice between cold and hot runner systems isn’t always straightforward. However, with the expertise and guidance offered by Precision Group, manufacturers can navigate this decision confidently, ensuring optimal outcomes for their molding projects.