Unleashing Precision: A Guide to Tooling Inserts and How Precision Group Expertise Can Transform Your Workflow

Introduction

In the world of machining and manufacturing, precision is paramount. Whether you are crafting intricate components for aerospace applications or producing high-performance automotive parts, the right tooling inserts can make all the difference. This is where the expertise of Precision Group comes into play, offering a transformative edge to your machining processes. In this article, we will delve into the significance of tooling inserts and explore how Precision Group’s proficiency can elevate your precision machining game.

Understanding Tooling Inserts

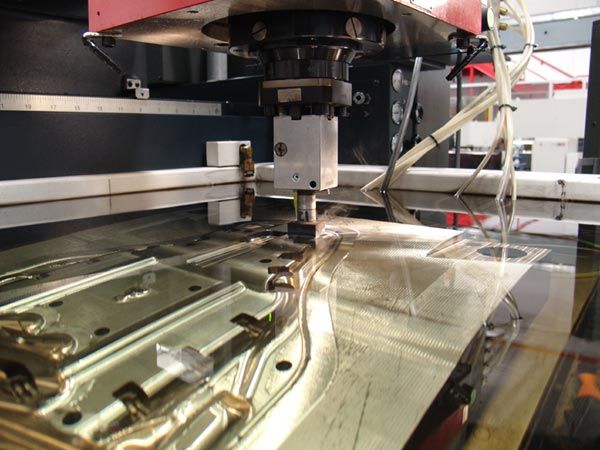

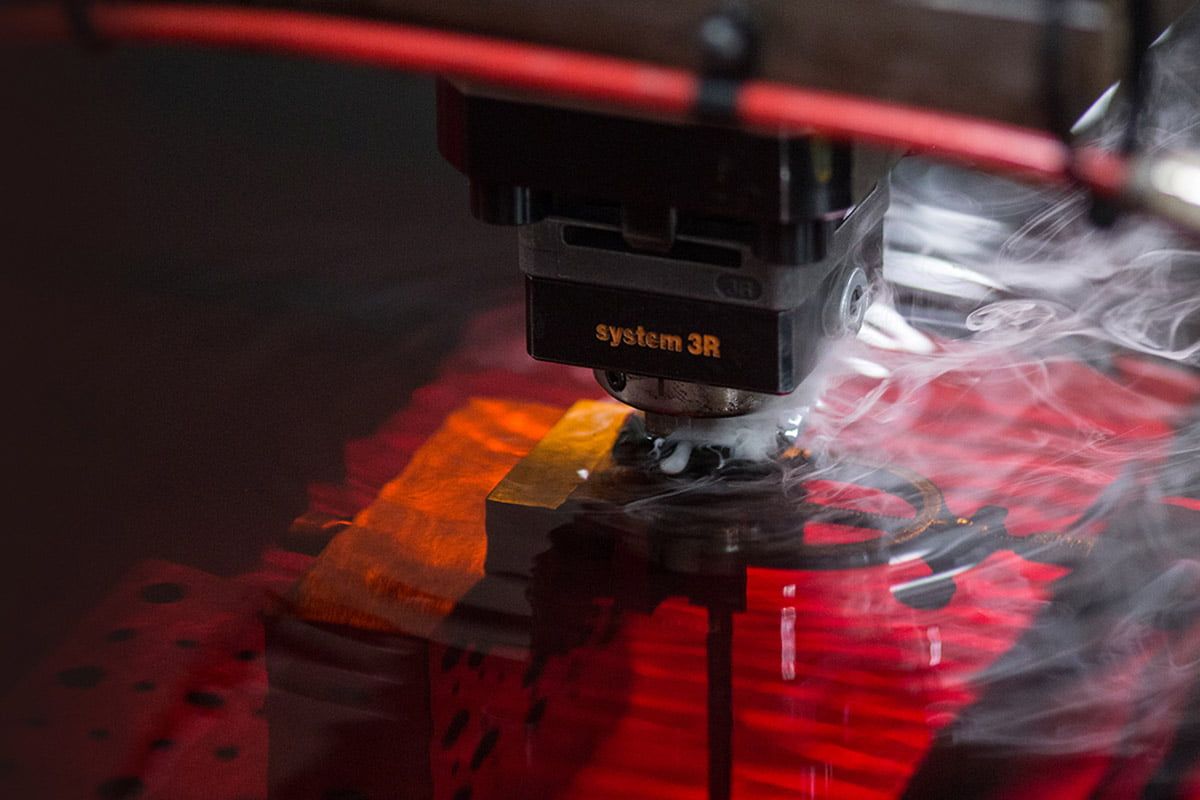

Tooling inserts are critical components in machining that play a pivotal role in shaping, cutting, and finishing materials with utmost precision. These inserts are typically made from hard materials like carbide, ceramic, or high-speed steel and are designed to withstand the harsh conditions of machining operations.

The Importance of Precision in Tooling Inserts

Precision is not just a buzzword in machining; it is the key to achieving optimal results. Tooling inserts with exact geometries and tolerances ensure consistent performance, extended tool life, and superior surface finishes. Whether you are working on turning, milling, or drilling applications, the right insert can make the difference between an average and an exceptional outcome.

Precision Group’s Expertise in Tooling Inserts

Precision Group has carved a niche for itself as a leading provider of precision tooling solutions. With a team of seasoned engineers and a commitment to innovation, Precision Group goes beyond the conventional, offering tailor-made solutions to meet the unique needs of its clients. Here’s how Precision Group’s expertise can benefit your machining endeavors:

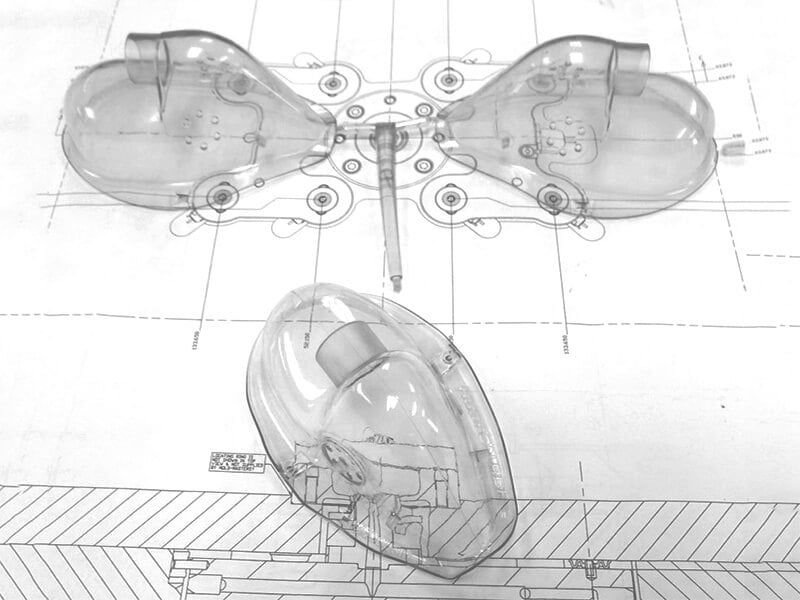

- Customization for Specific Applications: Precision Group understands that no two machining tasks are identical. With a focus on customization, they can provide tooling inserts that are specifically designed for your unique applications. This ensures maximum efficiency and performance in your machining processes.

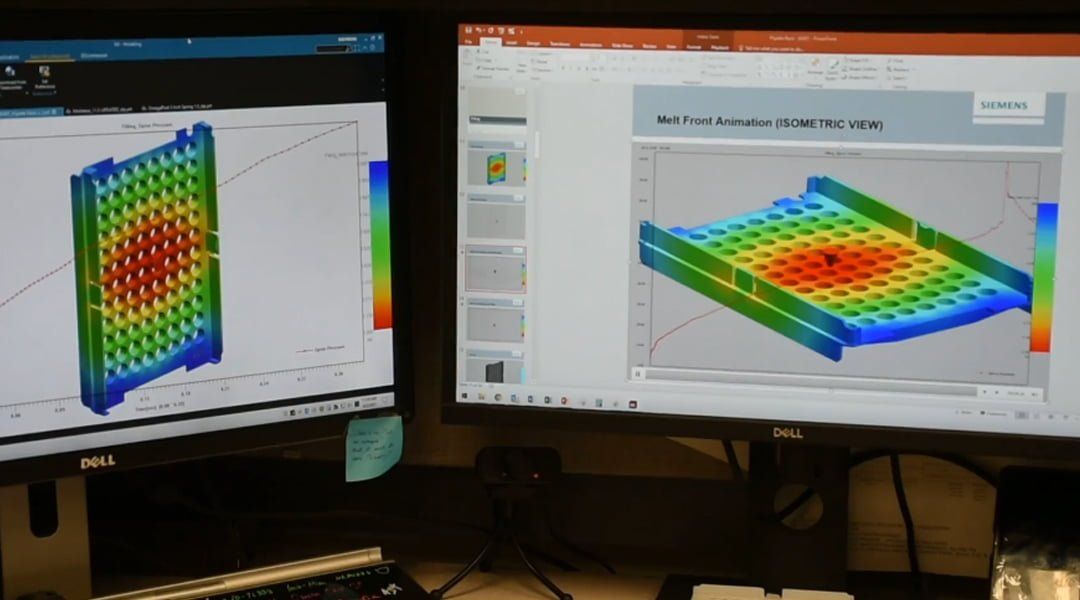

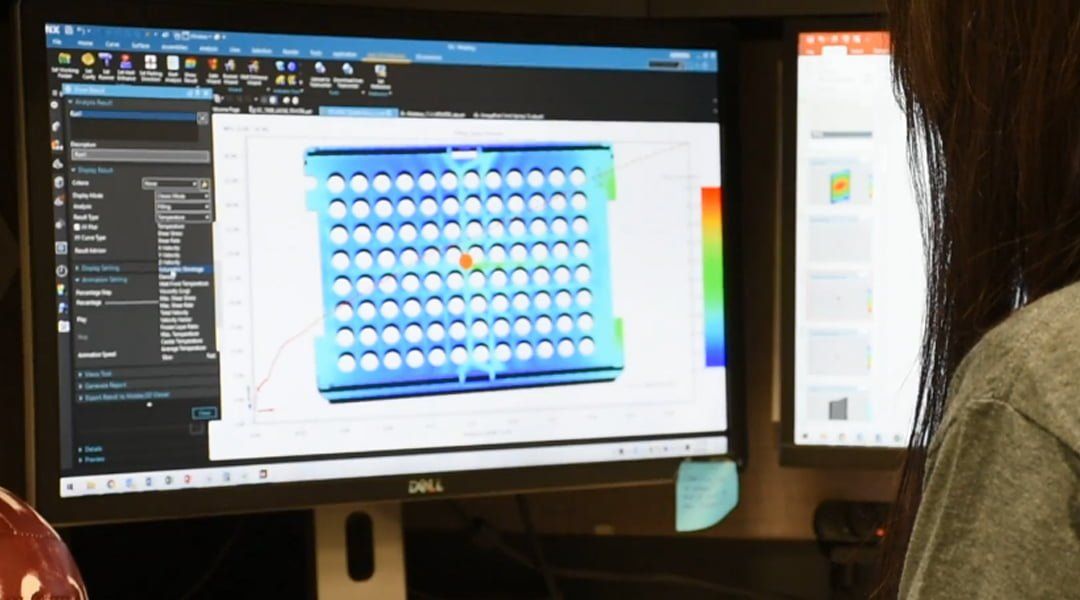

- Cutting-Edge Technology: Staying at the forefront of technological advancements is a hallmark of Precision Group. By integrating cutting-edge technologies into their tooling inserts, they empower manufacturers with the latest innovations, resulting in improved productivity and reduced downtime.

- Optimized Tool Life and Cost Efficiency: Precision Group’s expertise extends to optimizing tool life, a crucial factor in managing operational costs. By recommending the right tooling inserts and coatings, they help extend the lifespan of your tools, ultimately contributing to cost efficiency in the long run.

- Comprehensive Support and Training: Precision Group doesn’t just deliver tooling inserts; they provide comprehensive support and training to ensure that their clients extract maximum value from their products. This includes guidance on tool selection, machining strategies, and troubleshooting assistance.

Conclusion

In the intricate world of machining, where precision is the key to success, the right tooling inserts can be a game-changer. Precision Group’s expertise in crafting customized solutions, incorporating cutting-edge technology, and providing comprehensive support sets them apart as a reliable partner for manufacturers seeking to elevate their machining capabilities. By choosing Precision Group, you are not just investing in tooling inserts; you are investing in precision, efficiency, and the future of your machining operations.