Mastering Plastic Contraction in Injection Molding: Precision Group’s Expert Approach

Introduction

In the realm of injection molding, precision is paramount. Every molded plastic part demands meticulous attention to detail to ensure it meets exacting standards. One of the critical challenges in this process is plastic contraction – the tendency of the material to shrink or contract after molding. Understanding and managing this phenomenon is where the expertise of companies like Precision Group shines.

Unraveling Plastic Contraction

Plastic contraction is an inherent characteristic of the molding process. When molten plastic is injected into a mold and cooled, it undergoes a phase change from liquid to solid. During this transition, the material contracts due to the cooling and rearrangement of molecular chains. This contraction can lead to dimensional inaccuracies if not managed effectively.

Factors Influencing Contraction

Precision Group acknowledges various factors influencing plastic contraction:

- Material Properties: Different plastics exhibit different shrinkage rates based on their chemical composition. Understanding these properties is fundamental to managing contraction.

- Mold Design: Precision in mold design is key. The team factors in anticipated shrinkage and compensates by designing molds slightly larger than the final desired dimensions.

- Controlled Cooling: Managing cooling rates during the molding process can significantly impact contraction. Precision Group employs techniques to regulate cooling, preventing rapid or uneven solidification that may exacerbate shrinkage.

- Optimized Processing Conditions: Parameters such as temperature, pressure, and injection speed are meticulously adjusted to minimize shrinkage and ensure consistency in the final product.

Precision Group’s Approach to Contraction Management

Precision Group has honed an approach that sets them apart in managing plastic contraction:

Beyond Contraction: Precision and Innovation

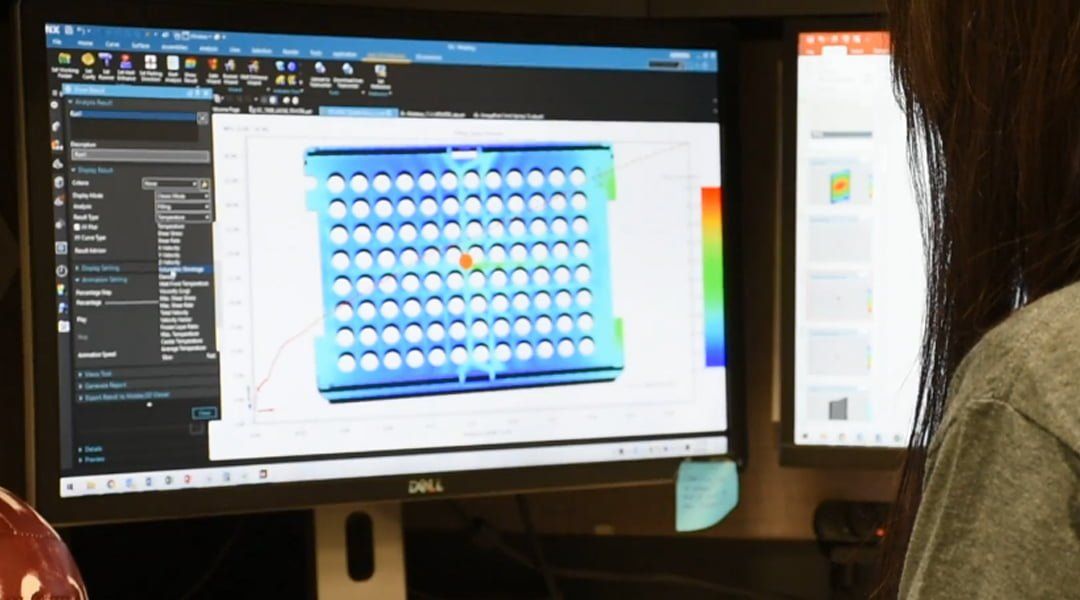

- Advanced Simulation and Analysis: They employ cutting-edge mold flow analysis tools that simulate the molding process. This allows them to predict and compensate for shrinkage accurately.

- Iterative Design Refinement: Their iterative design process involves constant refinement based on data from simulations and real-world molding trials. This meticulous approach ensures precise adjustments to mitigate contraction effects.

- Expertise in Material Science: Their team’s deep understanding of material properties enables them to choose the right plastics for specific applications, considering shrinkage tendencies and other critical factors.

- Quality Assurance Protocols: Rigorous quality checks at every stage of production ensure that parts meet stringent dimensional tolerances, even accounting for contraction.

Precision Group doesn’t just stop at managing contraction; they continuously innovate to push the boundaries of precision molding. Their commitment to research and development drives them to explore new materials, refine processes, and integrate emerging technologies to deliver unparalleled quality and accuracy.

Conclusion

Plastic contraction in injection molding is a challenge that demands finesse and expertise. Precision Group’s mastery in managing contraction through meticulous design, advanced analysis, and a relentless pursuit of perfection sets a benchmark in the industry. Their commitment to precision not only manages contraction but elevates the quality and reliability of every molded part they produce.

In the realm of injection molding, where precision is paramount, Precision Group stands as a testament to the fusion of art, science, and innovation.